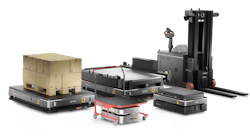

Creform Corp. has developed an automated guided vehicle (AGV) that delivers components from a company’s parts “supermarket” to its work-in-process locations.

The bidirectional AGV is a one vehicle system. It has three pickup points in the supermarket and 22 drop-off points throughout the operation. The AGV, used for auto-routing and safer handling, can travel between any two of the 22 locations based on a worker’s input. It operates two eight-hour shifts per day.

The system also incorporates a powered conveyor deck that holds pallets of powertrain components. The AGV’s conveyor accepts the load from one side of the unit and dispenses from the other. Its pallet is approximately 24 x 24 in. (600 x 600 mm) and weighs up to 600 lb. (272 kg) for robust handling of powertrain components.

The bidirectional AGV, Creform drive unit model FH-B350090, is mounted to a steel frame for strength and durability. Each end of the AGV follows the guidepath independently to ensure accurate and repeatable tracking that can operate in space restrictive areas and ensures alignment so that the conveyors smoothly and consistently transfer loads. The unit can travel with speeds up to 115 sfm (35 m/min) and can carry a load capacity of up to 1984 lb. (900 kg).

The AGV is PLC controlled and features two HMI touch screens that an associate can swivel to ensure access in space restrictive areas. The AGV uses floor positioned RFID tags for routing, speed changes and obstacle sensor view changes. The system also uses a peel and stick magnetic tape guidepath.