Vending machines have long been used as a vital element in tool management. Now there is a system designed specifically for MRO parts and maintenance cribs, CompuCRIB Automated Crib Management System. The reason: Automated cribs can help substantially reduce inventory, save floor space and save crib labor costs while ensuring that costs are being charged for jobs where they are used.

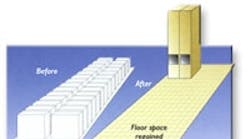

How MRO Parts/Tool Dispensing Systems Work In a traditional maintenance crib, tools and parts are dispensed from storage areas known as ‘cribs’. Sometimes the cribs are manned, which means that employees have to sign for the materials they use. Other times materials are left for employees to take as they need them: a situation that can lead to inaccurate inventories, waste and sometimes even theft. An automated crib based system is managed every step of the way. Your entire inventory of MRO parts and tools can be stored in vertical lifts capable of storing parts as large as 2000 lbs.. “When a person needs a part, they go to the system and input their ID” explains Tom Jamieson, president of ShelfPlus (www.compucrib.com). “Once recognized as authorized, the employee uses a touch-screen to specify the part/tool they need. The system then releases it, the employee takes it, and then gets back to work." Benefits By requiring the employee to log in every time they need material, an MRO can accurately track which parts are being used for which machines/orders at all times. This not only ensures accurate job costing, but it creates an easily-retrievable audit trail for budgeting true costs. Detailed reports show where products are being used and who is under and over budget, and give detailed information about each item's history. As well, “When Bill takes out a $2500.00 PLC controller from the crib, we know that he took it at 7 am, used it on Press 27 at 8:45 am,” says Larry Harper, president of WinWare, automated tracking allows MROs to accurately track parts on hand, and to minimize time lost due to out-of-stocks. This brings us to inventory cost reduction: an area where automated crib solutions shine. Experience has shown that when parts and tools are tracked to each job and department, inventory cost reductions can be expected in the range of 15% to 20%. “What really amazes people when they first install the CompuCRIB is the amount of floor space saved. One CompuCRIB can store the capacity of more than fifty sections of shelving of MRO parts, it truly is remarkable.” says, Gary Ash with Regal Tooling. By utilizing vertical space up to 41 feet, the CompuCRIB packs more high density storage capacity per cubic foot than any other type of system on the market. And with shelves of up to 120” x 32” and payload of 1200 lbs. per shelf even your largest parts can be stored safely. One of the big issues in managing any multi-shift maintenance crib is how to staff the crib on second and third shifts. Many plants struggle with balancing the cost of manning the crib vs using an open crib and facing inaccurate inventory levels. The CompuCRIB solves this problem once and for all. Off shift labor costs are eliminated by storing your parts in the security of the CompuCRIB System. Plant maintenance personnel have direct access to parts and supplies by password security. Each transaction is monitored and recorded with a time and date stamp thus allowing the customer to control an un-manned supply crib. The video monitoring system insures accuracy and control of the entire system. So how much money can plants save using automated crib systems? “Overall, we estimated that plants with some form of electronic parts management system can save 20 percent by adding our system,” says Cribmaster’s Larry Harper. “Those plants who are stilling using a manual system can save up to 40 percent.” The CompuCRIB system really is a vending system on steroids that will reduce your investment in the hardware store business and free yourself to concentrate on your core competency. Standing behind CompuCRIB are 20 years of continuous development of parts management and storage systems. This is why we can provide you with a proven, turnkey maintenance supply crib solution that will achieve everything we promise. About ShelfPlus and CompuCrib Since 1977, hundreds of satisfied customers have selected ShelfPlus for professional assistance with planning and implementing cost-effective manufacturing and storage facilities. CompuCrib combines the latest in automated parts storage equipment with specialized Windows®-based computer software to bring new levels of speed, efficiency, security and accuracy to MRO parts management. Contact : Tom Jameson 800-838-0473[email protected]