What happens at your workplace when you ask to see the performance indicators? Do you get that deer-in-the headlights look? Maybe you are presented with a chart that has no goals overlaid on the data? Or do you get a spreadsheet with a thousand lines of data with a lot of green and red?

In each case, it would be hard for anyone to quickly determine the health of the organization and respond when things go bump in the night. Unfortunately, many organizations don't measure performance at all, or measure the wrong things, or measure too much. This leads to a lack of clarity and focus, and slows reaction time when issues arise.

In order for an organization to determine how well it's doing, it must measure its processes—and it is critical to measure what matters.

Imagine going to the hospital for minor surgery and afterward waking up with thousands of electrodes affixed to your body. You can hear dozens of beeps and pings, and can see a large screen with hundreds of measurements on it. If something were to go wrong, where would the doctor look first? Would your medical team have to decipher hundreds—or thousands—of data points, sounds and signals before they could treat you?

Fortunately for us, the medical world has gotten measuring "vital signs" down to a science. These measurements of a body's basic functions are taken to assess the general physical health of a person, give clues to possible diseases, and show progress toward recovery. They call them vital signs for a reason; they are the five to 10 measures that are critically important for the body to continue functioning.

The business world needs to learn from this analogy so that when things do start going wrong in our processes—and they ultimately will—corrective action can be taken immediately before irreversible harm occurs.

One of the best methods for an organization to determine its own vital signs is through the use of a balanced scorecard. In 1992, Robert S. Kaplan and David P. Norton created this philosophy, which revolutionized the way organizational health is monitored. It starts with determining the top five to 10 measurements that are absolutely critical to overall organizational health.

These "performance indicators" should be identified for each area of cost, productivity, safety, quality, service and morale. It is a balanced scorecard because no one area is emphasized, and measures are taken from each core business outcome.

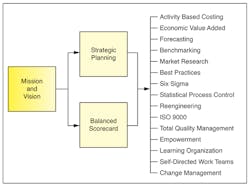

As Figure 1 shows, the measures should be aligned with the mission and vision of the organization, and rationalized during the strategic planning process. The goals and key performance indicators should be cascaded down the organization so everyone is working toward the same outcome.

Be SMART When You Set Goals

As important as establishing a balanced scorecard is, it is of little benefit to the organization if goals or targets have not been established for each metric. If it is important enough to measure, then it is important enough to have a goal or target. When establishing goals and targets, make sure to follow the SMART (specific, measurable, achievable, relevant and timely) criteria.

As the organization analyzes trends, or if an area is not meeting expectations, the organization should perform root-cause analysis and prioritize efforts. Since most organizations are dealing with a limited amount of resources, prioritizing actions is very critical to achieving results. There are usually simple and quick things that can be done to correct the issue. Start with the easiest corrective actions first.

Just as in a medical setting, if a trend or out-of-goal condition exists, then the organization responds with the appropriate "medicine," and other critical areas are monitored to ensure there are no negative impacts. Often, organizations focus solely on cost or service (or some other measure), which negatively impacts other critical measures; however, those other impacts are not noticed until the overall health of the organization is affected, simply because they were not measuring a broad spectrum of indicators.

In conjunction with incorporating a balanced scorecard approach, every organization should strive to establish leading measures rather than lagging indicators. If an organization only measures productivity or cost on a monthly basis, then it has lost weeks of reaction time. Also, the business is at a loss to what caused the bad outcome when it does get reported, because it happened weeks or months in the past. It's like trying to drive a car on a winding mountain road by looking in the rear-view mirror. If you look out the front windshield, you can see curves before you encounter them. Every organization should measure its core processes as close to the hourly time frame as possible. This way, you turn a lagging indicator into a leading indicator and gain weeks or months of reaction time.

All Eyes Should Be on the Prize

Finally, make sure everyone in the organization can easily see when the metrics are not met. This can be accomplished by using a Lean concept called visual management. The purpose is to make standards (goals) and current condition (measures) easily seen by all within the organization (Figure 2). When everyone can see the measures and whether the standards are being met, then questions can be asked about corrective actions. It does not do an organization any good if everyone does not understand the measures and standards and how they affect them. They should be visible to everyone from top management to hourly associates.

Every organization—whether it is a non-profit, manufacturer, or distribution center—should have a set of balanced measures to determine if it is achieving the goals of both the customer and its shareholders. These measures should have individual goals, and they should be visible to all within the organization. If an organization applies this methodology, it will be on track to lowering overall operating costs and gaining market share. You should be able to look at a dashboard or chart and quickly tell where the organization is hurting (Figure 3), so that corrective actions can be immediately implemented to bring the organization back to a healthy state.