Market analysts will look back on 2014 as a watershed year for fuel cells in the material handling sector. Fuel cells have proven to be both a competitive and productive technology in this application, enhancing efficiency while reducing the cost of warehouse operations.

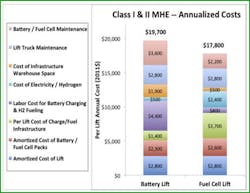

The advantages are many. Fuel cells offer longer run times than battery-powered forklifts and performance is consistent, with no voltage sag. Refueling takes just two to three minutes and can be performed directly by the operator, eliminating the need to staff a battery changing area, and reclaiming valuable warehouse space once devoted to battery storage. Fuel cells also operate without loss of performance in refrigerated storage and freezers, as well as in hot environments.There is a strong business case, too: fuel cell forklifts improve the bottom line. Preliminary analysis by DOE’s National Renewable Energy Laboratory (NREL) focusing on early fuel cell material handling equipment (MHE) deployments showed that, compared to battery-powered units, fuel cells offer a lower total cost of ownership, an 80% lower refueling/recharging labor cost, and take up 75% less space compared with battery recharging infrastructure. Overall, NREL found that the cost advantage per unit is about $2,000/year for the average high-use facility with Class I and II fuel cell lift trucks

REPEAT CUSTOMERS

Plug Power, a fuel cell manufacturer concentrating on this market, received multiple follow-on orders in 2014 from major companies looking to expand on their fuel cell success stories. These companies have deployed fuel cells at one or more of their distribution centers and have experienced the fuel cell value proposition firsthand. And they are coming back for more

The biggest news of 2014 was Walmart’s order for 2,069 Plug Power GenDrive fuel cells for deployment at seven of the company’s distribution centers. The purchase order also includes Plug Power’s GenFuel infrastructure and hydrogen fuel supply and GenCare maintenance. This will make Walmart the largest user of fuel cell forklifts worldwide, with roughly 2,600 fuel cell-powered forklifts at 10 sites in North America.

Walmart initially tested 18 fuel cell forklifts at its Missouri and Ohio warehouses during 2006-2008 and, following these successful demonstrations, began adding fuel cells to other facilities. Fuel cell-powered forklifts now operate at Walmart distribution centers in Ohio (254 units) and Oklahoma (more than 200), as well as at its Canadian warehouses in Alberta and Ontario (95 and 174 units respectively). According to Johnnie Dobbs, Walmart’s executive vice president of logistics and supply chain, "We’ve seen how fuel cells improve efficiency in our distribution centers while allowing us to be more responsible global citizens.”

Ace Hardware is another returning customer. The company tested six fuel cell forklifts at its Sacramento, California, warehouse in 2008 and followed on with orders for fuel cells for its new Wilmer, Texas, Support Center (65 fuel cells) and its Rocklin, California, support center (undisclosed number). More recently, Ace placed another order for 71 fuel cells to power Class II and III lift trucks at its newly constructed West Jefferson, Ohio, site. Nuvera Fuel Cells’ PowerTap hydrogen generator and dispenser is supplying fuel at the Ohio and Texas sites.

BMW's entire fleet of material-handling trucks and forklifts in its Spartanburg, South Carolina, production facility is now equipped with hydrogen fuel cells from Plug Power. Their original fleet of 100 forklifts was expanded in 2013 to add another 175 units, bringing the facility’s clean-energy fleet to 275 units. These forklifts are used in the assembly hall for its X3, X5 and X6 automobiles and in its paint and body shops. The BMW fuel cell forklift fleet at this time is using more than 700 kilograms of hydrogen daily and next year with the expansion of its facility; this will increase to over a 1000kg/ day usage. The liquid hydrogen supplied from Linde originates from renewable sources.

Golden State Foods and Newark Farmers Market have also placed repeat orders. In 2011, Golden State Foods installed 20 methanol-powered Oorja Fuel Cells to extend the range of battery forklifts operating at its Lemont, Illinois, site. The company’s new Chicago area food distribution center, serving more than 460 McDonald's in the Midwest region, features Plug Power GenDrive fuel cells that power 11 Class II stand-up reach lift trucks and 28 Class III rider pallet trucks, with hydrogen generated on-site by Nuvera's PowerTap system. Newark Farmers Market in Newark, New Jersey, also recently announced that it will more than double the size of its fuel cell forklift fleet with a follow-on order of 110 GenDrive fuel cells.

Central Grocers ordered 182 fuel cells to replace its original fuel cell material handling fleet at its Joliet, Illinois facility, which the company has had in place since 2009. These fuel cell-powered Class II and Class III lift trucks delivered more than two million hours of service. Ken Nemeth, president and CEO of Central Grocers, reports that, “Hydrogen fuel cells run longer and maintain consistent power as they operate and are refueled more quickly than batteries. Our operators are pleased with the lift trucks powered by GenDrive, and management has been impressed by the high levels of productivity within our facility."

International Interest

Fuel cell forklifts deployments are also growing internationally. New Kansai International Airport Co., the operator of Japan’s Kansai Airport, is launching a new hydrogen energy grid project at the hub airport. For the test program, two fuel cell-powered forklifts will begin operation at the airport’s shared drug storage, cargo shed and other areas. A full-scale hydrogen station will be built to fuel the forklifts and other fuel cell electric vehicles that will operate in and around the terminal area.

In Europe, heating and renewable energy product manufacturer Viessmann announced that it is operating a fuel cell-powered Still forklift truck in daily operations at its factory in Allendorf, Germany. Viessmann plans to generate renewable hydrogen onsite using methane from the company’s biogas plants; the electrolytic process will be powered by wind or solar energy.

The BMW Group, Linde Material Handling, and the Institute for Materials Handling, Flow and Logistics (FML) at Technical University of Munich have been awarded a grant to develop a fleet of hydrogen fuel cell powered forklift trucks and tow tractors for logistics trains. The project has established a fleet of fuel cell industrial trucks at the BMW automobile production plant in Leipzig also where the electric i3 and i8 vehicles are produced.

And there are more to come: the HyLIFT-EUROPE project, now underway, will demonstrate up to 200 fuel cell material handling vehicles and refueling infrastructure at 10 to 20 sites across Europe, making it the largest European trial of hydrogen fuel cell MHE and the world's first large scale demonstration of airport tow tractors.

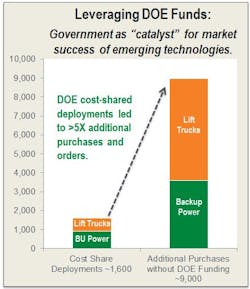

Growing Sales

To give the then-nascent application a lift, DOE provided about $9.7 million in cost-shared funding through the 2009 American Recovery and Reinvestment Act (ARRA) to encourage U.S. companies to try out fuel cell technology in material handling and backup power applications (industry cost-share in this effort was $11.8 million.) This investment turned into a success story for both applications, leading to a fivefold increase in fuel cell purchases without additional ARRA funding.

The Future is Bright

Fuel cells are also moving into promising new areas. Plug Power is working with DOE to demonstrate a fuel cell tow tractor at Memphis-Shelby County Airport, while Plug Power and Nuvera, along with Sysco Corp. and H-E-B Grocery Company (with funding from DOE) will test the use of fuel cell-powered transport refrigeration units (TRUs) in semi-trailer trucks that carry perishable and frozen foods. In both instances, fuel cells will provide efficient and quiet power generation while minimizing localized emissions. Kriston Brooks, the Pacific Northwest National Laboratory researcher leading the TRU fuel cell project, says that, "One of the goals is to accelerate fuel cell use in industry. In spite of their higher costs now, the higher efficiency and zero emissions from fuel cells are enough to convince many companies not to wait to implement this technology. Fuel cell products are already used widely in warehouses, and this project broadens their reach."

As Plug Power puts it, "It’s clear, hydrogen fuel cells are tomorrow's incumbent power sources, available for use today."