Save Millions by Correctly Calculating Distribution Capacity

One of the toughest questions we get asked is, "What is the optimal capacity for my distribution operation?" Choose a number too low and you can't fulfill all your customer orders. Choose a number too high and you've over-invested in distribution capacity—potentially by millions of dollars. So how do you determine the optimal distribution capacity?

Average daily volumes won't work for calculating distribution capacity where e-commerce is concerned. This kind of business is volatile and changes hourly. If you promise customers to ship orders the day you receive them, you'll likely experience peaks and volatility around order cut-off time. For these types of operations your analysis must consider hourly volumes, not daily volumes. Companies that calculate capacity needs based on daily volumes end up costing themselves—either by building a DC with more capacity than needed or one that can't meet demand during critical times.

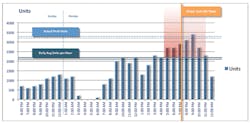

By focusing on hourly values in conjunction with order cut-off times, you can also take into account hourly and seasonal peaks. Consider the following example from a major fashion retailer (Sunday, 6 pm – Tuesday, 1 am) shown in Figure 1. If this retailer had designed their distribution capacity to handle the average of 2,300 units per hour, they would not be able to fulfill the surge that comes in just before the order cut-off time (red highlighted area).

On the other hand, there is no reason to design to peak, either (gold highlighted area). Frequently, e-commerce orders continue at a high rate even after the order cut-off time—usually into the early evening. When the capacity is set to a value lower than the peak, this can cause a backlog in orders that may look concerning when, in reality, there is almost a full 24-hour cycle that can be utilized to eat away at that backlog. This illustrates another point: Daily values can be deceiving if your day is not defined properly. The 24-hour cycle you need to be concerned with is order cut-off time to order cut-off time (in this case, 7 pm to 7 pm, and not 12 midnight to 12 midnight).

So, as with designing with too little capacity in terms of missing orders, there is the risk of overspending on capital expenses that yield no real improvement in service or benefit to the bottom line.

In setting capacity, we are attempting to specify the minimum capacity level that allows us to minimize missing orders placed before our cut-off time and to also work off any backlog that occurs after the order cut-off time before the next peak period occurs.

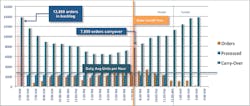

This retailer only works 18 hours a day and not at all on Sunday, so they enter Monday with a significant backlog (13,800 for this particular Monday). For that reason, they chose to set their capacity based on Monday operations.

Figure 2 shows what will happen if they set their capacity at 2,300, the average hourly volume needed to process daily orders. As can be seen, there is not enough capacity to work through the backlog before heavy orders begin to accumulate before the order cut-off time. They would disappoint 7,800 customers on this Monday. Even raising the capacity to 2,700 units (the peak that occurs before the cut-off time) would disappoint 2,000 customers.

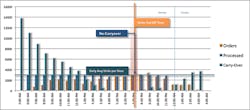

With a capacity level of 2,900 units the backlog can be worked through before the order cut-off time without providing capacity that is not used. In Figure 3 you can see how demand is carried over past the peak, where it is worked off in the early part of the day. We can also see that the carry-over headed into Tuesday is less than what is carried over from Sunday, which provides confidence that Monday is the correct day to use to set capacity for this retailer. Our example only covered one Monday, but this analysis would need to be conducted for multiple Mondays, with capacity set accordingly.

How to Incorporate Peak Season into Your Approach

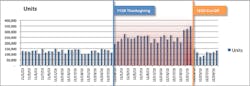

But how would you incorporate peak seasons into this approach? For example, if you were to experience the daily demand (defined between two consecutive order cut-off times) of the online retailer shown in Figure 4, which day would you pick to use in the previous analysis? The "average" day?

Again, design by averages doesn't work. If you build your facility for an "average" day, then you very likely have too much capacity for a large percentage of your days and too little for the peak season(s). You need to balance service expectations against cost as you plan for the flexibility you'll need to handle those peaks. That plan may include alternative flow paths, outsourced additional labor, manual processing, adding shifts and/or increasing shift hours. Keep in mind that both equipment and systems have to be designed to support the plan as well.

For example, an online retailer chose to use a unit sorter to fulfill a large percentage of its demand. During non-peak season, the unit sorter was run with one induction station. However, during the peak season, the same sorter was configured with four induction stations.

For any company some variation on the strategy of choosing an appropriate capacity that covers non-peak season and then using the same capacity or enhanced capacity in new ways to address peak seasons can work well. And when it can't (handle peak seasons), capacity in non-peak season needs to be adjusted upward until a balance is achieved.

So how do you determine the optimal design capacity? The key is being able to adjust the processing capacity to the appropriate level of acceptable risk, without "oversizing" the facility.

Now that you have analyzed your hourly, daily and seasonal peak demand, and applied growth for the future, you are ready to look at the levers that allow you to adjust the size of your operation to budgetary or other constraints and determine the optimal design capacity to satisfy the needs of the business.

Order cut-off time is one of several levers you can use. Keep in mind that processing capacity and availability should be aligned and balanced to handle "end-of-day" cut-off requirements for delivery carriers. Order cut-offs must be synchronized with carrier pull times and available capacity so that there's sufficient time to process the orders and load them onto outbound trailers to meet required service levels. With fixed pull times and insufficient capacity, the only option is to move order cut-off times earlier, which will negatively impact customer service. However, negotiating a later pull time (while keeping order cut-off time the same) can help reduce capacity requirements by allowing extra time for processing. But later cut-offs can have unintended consequences.

By extending its next-day delivery order cut-off time to 8 pm, the latest in its industry, one industrial distributor found that its customers held items in their shopping carts throughout the day and placed larger orders later in the day, causing a surge—even larger than it experienced previously. That required additional capacity to be built for their operation.

And there are things you can do with labor such as stagger shifts or change the way you plan work to meet capacity requirements. Temporary measures such as expedited shipping can help alleviate the occasional capacity crunch, but if you find it difficult to align capacity with constraints it may be necessary to look longer term and consider a change to your network strategy (how many facilities and where they are located). Being clear about your service level objectives and tolerance for risk is critical when setting capacity levels.

Russ Meller is vice president of R&D for Fortna, a global distribution services and engineering firm, and a member of MH&L's Editorial Advisory Board. Barry Webb serves as a project director for Fortna in their Supply Chain Services Organization, where he is responsible for the design and delivery of material handling solutions to help Fortna clients solve complex distribution and supply chain challenges. He has been serving the supply chain industry for nearly 30 years and holds an Industrial Engineering degree from The Georgia Institute of Technology.