Demanding customers, emerging technologies, global supply bases and ever-changing market landscapes require companies to continuously adjust their supply chains to stay competitive. Most supply chain executives find themselves trapped in a vicious cycle where every new or newer technology presents the panacea that the previous version could not address. To break the cycle, rather than reaching for the latest technologies, some managers have gone back to basics and have emerged with lasting return and a competitive advantage.

The Issue

Over the last couple of decades, the Internet has made customers increasingly more discerning and selective of products and services. Companies in all industries are responding to customers’ changing needs by making their supply chains more agile. While all supply chain executives see the need to transform their supply chains to be more efficient, few are confident of the starting point. Most gravitate towards the latest technology solution, be it strategic sourcing application, advanced supply chain planning software, manufacturing execution system, or a warehouse management system.

However, in order to create effective change, managers need to start with the basics before considering any technology enhancements and revamps. What follows is an illustration of the value of supply chain basics focusing on MedD, a mid-sized medical devices manufacturer and distributor. (Note: The name of the company and some of the financials have been changed to protect company information.)

The founders of MedD were considering selling their company to a private equity firm. One of the founders wanted to improve profitability to afford them a better market valuation. To do so, they focused their efforts on supply chain costs and performance.

A recently hired supply chain executive was tasked to enhance the performance and reduce the cost of the supply chain. With inventory fluctuating from $110 million-$170 million, an order fill rate less than 75%, forecast accuracy around 50% and an end-to-end lead time greater than 150 days, the number of areas to improve supply chain performance were overwhelming. The supply chain officer’s knee-jerk reaction was to revamp planning software technologies and focus on better forecasting. However, he needed to look back to basics to find a solution.

The Solution: Back to Basics

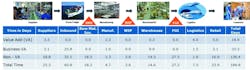

It is critical to examine the basics of any supply chain before an improvement strategy and trajectory can be designed. Companies should develop an end-to-end (E2E) value stream map to understand their basic supply chain configuration and performance. Figure 1 below shows the supply chain value stream for MedD.

Basic value stream analysis quickly reveals the health of a supply chain. In the case of MedD, the E2E product lead time of about five months did not give leadership any reaction time to efficiently adjust to market changes. It also became apparent that the majority of the production time was spent waiting in various non-value-added activities: waiting for raw material replenishments; waiting for goods to be manufactured by suppliers; waiting to be shipped to the U.S.; waiting for value-add services in U.S. warehouses; and then waiting to be shipped to the customer or the final consumer through e-commerce channels.

The supply chain E2E lead time also proved to be greater than 184 days. Figure 1 shows the breakdown of this time in value-add and non-value-add activities. Any supply chain with greater than 100 days of non-value-added waiting time cannot react fast enough to any customer- or competitor-driven changes in the marketplace. This insight challenged MedD’s competitive position.

Armed with this information, MedD identified three major areas of non-value-added time on which to focus the initial supply chain transformation effort. These areas, with respective measurable goals, were:

● Reduce non-value-added supplier process time from 18.8 days.

● Reduce the non-value-added inbound transportation time from 53.3 days.

● Reduce U.S. warehouse dwell time before shipment to customers from 41.6 days.

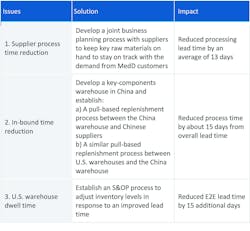

Table 1 below shows the solutions that were developed for each of these three areas by addressing basic supply chain principles.

Results

Organizations get back to basics by evaluating drivers of the end-to-end lead time, targeting basic process changes within the four key areas of supply chain (Plan, Source, Make and Deliver) and applying solutions to improve key area fundamentals, which ultimately drive dramatic improvements in the end-to-end supply chain agility.

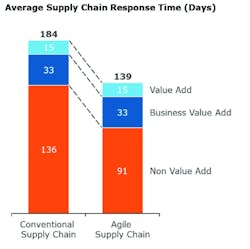

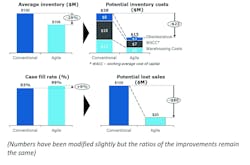

By analyzing the E2E lead time and identifying areas of improvement in sourcing, inbound transportation and planning, MedD was able to develop targeted solutions, resulting in significant operational and financial gains (see Figures 2 and 3 and Table 2 below).

In addition, E2E supply chain performance visibility allowed MedD to clearly understand the limitations of current planning technology solutions that were impeding refinement of their inventory levels both at the supplier and at U.S.-based warehouses. MedD further detailed a roadmap to implement a technology solution that enabled sales and operations planning and inventory level optimization.

Ultimately, the new MedD supply chain executive created a successful transformation of the supply chain in less than a year, enabling the company to focus on the future with a nimble supply chain. Once supply chain managers optimize the basics—from reducing E2E lead time and inventory to increasing agility—they can effectively deploy the Internet of Things to enhance end-to-end visibility, rationalize product portfolio and implement an advanced supply chain planning tool to further secure and improve their competitive position.

Udit Sharma, managing director at business advisory firm Riveron, is responsible for client service, specializing in supply chain improvement, EBITDA enhancement and operational due diligence.