“We deploy, at a premium cost, a product that may not be needed, from sites that may struggle to ship it to sites that may not be able to receive it.”—VP Transportation, Fortune 50 company

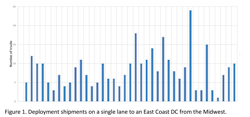

Deployment—shipping from plants to customer-facing distribution centers—is critical for ensuring customers get needed products when they want them. Deployment plans are based on what is needed to meet safety and cycle stock levels on a SKU-by-SKU basis. Customers’ demand varies. Together they drive huge volatility in volume on any site or lane. A real-life example of this for two months is shown in Figure 1.

In this example, which is by no means atypical, managing the throughput of 24 loads on one day and three on the next has significant impacts on labor and is a massive challenge for the transportation group. To find 24 trucks, transportation analysts must go deep into the routing guide and sometimes call around to cover the loads. At the receiving location, some of the 24 trailers pile up, waiting to unload. In addition to incurring detention, these trailers may carry a product needed for a customer and shipment. This adversely impacts on-time and in-full shipping to key customers. Under pressure to quickly unload the shipment, DC managers often incur substantial overtime labor.

Even the latest supply-planning systems don’t adequately consider carriers and warehouse operations when making deployment decisions. Deployment plans don’t generally consider cost or feasibility. What if there is:

• Insufficient space at the receiving location?

• Production trying to push into a plant warehouse that is already busting at the seams?

• A need to add cost in the form of overtime in the shipping location or hire a carrier that is way down on the routing guide because of cost or service?

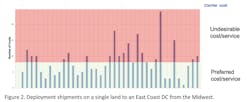

Actual daily deployment shows the carrier cost of this vast variability (see Figure 2).

Bridging the Gap between Planning and Operations—It’s Hard

The challenge is converting a potentially infeasible or, at best, a highly volatile supply plan into a smooth, level-loaded plan that:

• Meets the capability of the warehouse to receive while shipping to customers.

• Allows transportation to secure “preferred” carriers.

• Minimizes costs for:

o Freight

o Overtime

o Detention.

· Maintains or improves service to the customer.

There may be many reasons this deployment problem has yet to be solved. Some reasons revolve around awareness and the scale of operations. Supply planners may not recognize the operational havoc and cost they generate, but even if they do, coordinating among themselves to trade off thousands of lines of deployment requirements is a daunting, maybe impossible task.

Another reason that this deployment problem hasn’t been solved before is that it is very complex:

• Every lane must be treated as part of a holistic system (see Figure 3). You can’t fix the space issue at one warehouse at the expense of another site.

• Most large companies deploy in full truckloads. Many lanes may flow into one space- or throughput-capacity-constrained warehouse, so what is the most important product to ship? The limitation and priority must translate into which trucks should be built from which supply points.

• And, of course, there is the problem of transit time. Any customer-facing DC may have many sites shipping to it with various lead times. When will the product arrive? Will there be space, then? A complex time series must be solved as each preceding day impacts the following days.

Bridging the Gap between Planning and Operations—but It’s Been Done

The bridge between planning and operations is a bolt-on tool to the planning solution incorporating a wide range of supply-chain constraints. That is, take the planning output and create a leveled, low-risk, high-service, cost-effective plan.

Using operations-research techniques like linear programming (or its much slower cousin, integer programming) could meet the need for a holistic approach. Still, linear programs do a poor job of creating truckloads—the primary currency of high-volume deployment. Solving for some near-optimal way of putting products on trucks requires understanding that some products can stack on top of other items in a truck, while others cannot. Solving the loading problem for thousands of trucks and doing this many times as alternate scenarios are considered needed to be ultra-fast. Otherwise, the time to produce a network-wide plan could take too long.

Using artificial intelligence in the form of reinforcement learning, combined with heuristics, solves this problem. Now, good loads can be produced and produced fast. The output is a smoother deployment plan—every truck on every lane out into the future.

Turning a Level-loaded Plan into Action

Knowing every load on every day on every lane is nice. Some companies see value in transportation forecasting—sending carriers their expected workload over the coming days. This may add significant value to large carriers, but has limited value to most of North America—a fragmented carrier market.

An added value of the leveled deployment plan is that it allows tendering loads into the future, i.e., providing a carrier with a commitment. But there is a catch. Traditionally, the way tendering is done is to create a stock transfer order with all the required items defined. But the problem with tendering shipments many days before shipment is that the quality of the supply planning requirements is constantly improving closer to the ship date.

To get the most-needed product deployed, the approach is to create a stock transfer consisting of a “placeholder” or “dummy” item. This initiates a tender through the ordinary course of events. Later, just before loading, the stock transfer can be updated with the highest-quality, latest requirements.

But there is another important consideration. The number of loads tendered may not match the requirements. If there are more requirements than loads, then only the high-priority product (e.g., measured in days of supply) should be added to the available trucks. If there are more trucks than are needed for that ship date, pull forward requirements. In this way, the truck is reserved early but the load is defined late—when the supply planning system is projecting needs with improved accuracy.

Determining the highest possible payload while ensuring that the highest priority product is on a defined number of trucks (that were tendered many days earlier) is a significant optimization challenge handled by more operations research techniques and AI.

Leveling, Load Optimization and Early Tendering Works

The results have been impressive:

• Thanks to AI, large networks with thousands of weekly deployment loads are solved in minutes.

• Loads are tendered without planner intervention.

• Loads are tendered days earlier, driving first tender acceptance of preferred carriers well above the previous best.

• As a result of the above, costs are down while service levels are maintained.

• Lanes are smoothed, and sites see a much more even flow of work.

Most importantly, AI and other advanced technology available today have enabled a solution that bridges the gap between planning and operation that is scalable; reflects the real world; easy to maintain; reduces the need for planner intervention; and saves money.

Experience shows that these leveled plans, load optimization and early tendering meet or exceed the required customer service standards.

The benefits don’t stop there. There are significant, longer-term benefits, the biggest of which revolves around carriers. Carriers value predictability and reward shippers with improved service and lower costs. In some cases, it is possible to guarantee daily lane volume, resulting in even lower costs.

Technology Has Made All This Possible

Five years ago, the AI technique called reinforcement learning was nascent. Today, when combined with other technologies, if it solves an impossible-to-solve problem and bridges the gap between planning and operations, the savings are significant. The value across the supply chain cannot be underestimated.

To rephrase the VP of transportation quoted above, “We deploy at the best cost the product that is needed from sites that can ship it to sites that can receive it.”

Tom Moore is CEO and founder of ProvisionAI, a provider of supply chain optimization solutions.

About the Author

Tom Moore

Tom Moore is CEO and founder of ProvisionAI, a provider of supply chain optimization solutions.