Global Volatility & AI: How It Will Affect Your Supply Chain

Geopolitical and market events promise to make 2019 a challenging year for supply chain and procurement teams, one full of both increased risks and opportunity. Forward-thinking professionals are looking to new technologies to help them make the most of it.

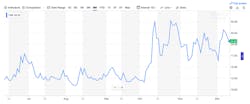

1. Geopolitical Risk Will Increase Volatility

Managing geopolitical risk has always been a part of procurement and supply management’s job, but as new sources of supply volatility emerge and the threat of tariff escalations increase, managing these risks has become critical.

In addition to the standard sources of risk - typhoons, hurricanes, factory fires and labor disputes, world events have created new sources of risk that were unforeseeable a few short years ago. Traditionally a stabilizing influence, U.S trade policy has become less predictable. Looming largest is the uncertainty surrounding the immediate future of the trade relationship between the U.S. and China. Recent tensions continue to increase and show few signs of abating. In combination with mixed messages from the Trump administration that send markets surging or tumbling on any given day, volatility will continue into 2019.

Tariffs aside, manufacturing in China has been buffeted by security concerns and rising wages, making the region less attractive to manufacturers. A substantial number of organizations are going to begin planning significant shifts in their supply chain operations. Management will have to weigh their options carefully, however. China dominates the manufacture of certain components, so while a move to Vietnam or Mexico might allay some concerns, it will create others around quality and part availability.

Source: CBOE Volatility Index. 6 months ending 12-Dec-2018.

Taken together, these risks and impending changes are going to increase the demand for scenario planning from procurement. Teams will employ “what if” situations that run through different possibilities to determine the potential impact on supply and find ways to mitigate this impact, like identifying new suppliers or changing to suppliers in different locations. Being able to forecast and prepare for a range of possibilities is going to require software technology beyond what many organizations employ now.

2. Cost Inflation Will Change Procurement’s Achievable Goals

For the past five to seven years, in an environment of overall declining prices in technology industry, driving cost reduction has been the relatively straightforward and the standard measure of procurement success. Volatile markets have shaken the assumption behind slow but consistent cost reductions however, and many electronic manufacturers will need to shift their goal to ensuring continuity of supply and perhaps limiting price increases.

In addition to tariff threats, higher interest rates, and wage growth, tech components are increasingly being incorporated into “non-tech” products, which is contributing to higher overall demand. Procurement organizations will need to be more creative to obtain cost reductions or simply manage cost increases.

Source: Federal Reserve Bank of St. Louis Economic Research

3. Organizations Will Increasingly Experiment with AI Adoption

As managing risks and identifying successes becomes more challenging, companies will begin to look for solutions beyond their current capabilities. In addition to existing digital transformation initiatives, more organizations will launch pilots or test limited rollouts of AI-enabled technology, the continuation of a trend we have seen that over the last few months.

At LevaData, we’re seeing a high degree of interest and adoption of new technologies among the enterprise procurement and sourcing teams we regularly work with:

State of Digital Transformation Initiatives Among Enterprise Supply Chain Teams

| Mature Initiative: 2+years: | 21% |

| Active Initiative: 1-2 years: | 21% |

| Initiative launched: < 1 year: | 33% |

| Planning initiative launch: | 7% |

| No plans: | 19% |

For many organizations, predictive technologies will serve as a halfway point between automated processes and an AI-led business. Most organizations have already automated some of their processes. The next logical step is implementing predictive technologies and identifying how AI can assist in making decisions based on potential outcomes. Applying predictive models around specific areas of spend is an appropriate stepping stone to a full AI-driven approach.

4. Market Leaders Will Engage NPI and Sourcing to Optimize Life Cycle Costs

Market leaders using AI-enabled tools in sourcing will soon recognize the benefits of these tools in product design, where 70 to 80% of a product’s life cycle cost is set. This will allow New Product Introduction (NPI) to model scenarios providing insight into how specific parts and suppliers could impact gross margin and reduce supply risk over time. Over time, the use of new technologies and collaboration between procurement and NPI will help these companies meet shorter product development cycles and ultimately provide a competitive advantage.

5. Greater Focus on Digital Literacy Among New and Existing Talent

A growing awareness of the benefits of AI-enabled tools will encourage managers to look for new hires with a high degree of digital literacy, and improve the skills of their existing SMEs. The integrated technologies that take the place of unwieldy spreadsheets will also help bring developing professionals up to speed. At the same time, investment in technology training will increase as commodity managers will be expected to become comfortable with new technology and the changes it brings to their routine.

The 2018 Cognitive Sourcing Study found that 85% of executives believe data-driven procurement is important, but only 46% think their teams are ready to accommodate new technologies.

About the Author

Rajesh Kalidindi

founder and CEO

Rajesh Kalidindi is founder and CEO of LevaData, a company that delivers applied AI to transform strategic sourcing and procurement.