A Path to Damage Prevention for Intermodal Transport

The supply chain industry has seen a shift in transportation strategies as manufacturers and retailers look for ways to satisfy their customers, overcome driver shortages and reduce overall shipping costs and environmental impact. As fuel costs increased following the recession, the cost of shipping freight via truck trended up, forcing manufacturers to review all options for getting their products from their facilities to a retail shelf. The shortage of truck drivers in the U.S. is also reshaping the industry due to a combination of industry growth and a retiring workforce.

As a result, intermodal transportation has become a cost-effective solution for moving large amounts of freight across greater shipping distances. This shift in transportation modes is changing packaging requirements for shippers that want to protect product quality, reduce costs and minimize liability risk.

Considerations for Intermodal Shipping

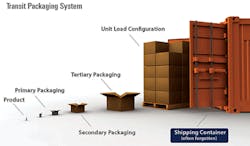

Intermodal transportation involves moving freight in a shipping container or vehicle, using various modes of transportation, without ever handling or checking on the condition of the freight within the container after it is loaded (see illustration). With increased limitations and costs associated with traditional truck shipping, a single shipping container can travel via road, rail and ocean before arriving at its final destination.

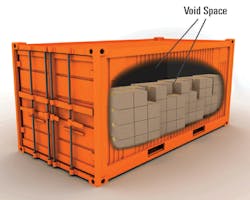

Packaging professionals are faced with the challenge of finding the optimal packaging system that balances costs against protective need. Trends such as light-weighting and material reduction can lessen the impact of some safety measures for intermodal shipments because freight can become more susceptible to side-shifting and dynamic compression hazards. Packaged product can easily interact with other freight within the container.

Will Intermodal Transport Affect Your Packages?

While standard distribution testing is widely used and aims to predict the effects of shipping packaged products through very generalized conditions, it is not feasible to account for every "what if" scenario. Even with a comprehensive validation program, packaging systems can pass validation testing and perform poorly when shipped.

With intermodal, most rail containers are loaded by manufacturers, the majority of whom lack the expertise in blocking and bracing provided by logistics experts. If a brand owner is not accustomed to working with intermodal shipments, they could neglect to consider certain facets of the supply chain. For example, "hunting" is a common root cause for damage and occurs when rails are not perfectly straight and the railcar has to search for the track. Because the product container doesn't get touched until it is unloaded, damage discovered at the final destination can cause material handling professionals to lose time in the field from cleaning up product messes.

Understanding these differences up front can help brand owners work either internally, with a third-party testing lab, or a logistics provider to identify key factors that represent their specific transport system. As a strategic partner, test labs can help both brand owners and logistics companies prevent potential damage issues, analyze situations where failures have occurred and recommend solutions. To maximize efficiency, it's also important to ensure contracts consider the transit system, and include instructions on how to load the containers in a manner that's most likely to protect the product.

Testing laboratories can create a generalized hazard map and testing plan for intermodal shipments that can help predict potential damage and ensure the freight is protected from issues that can occur while in transit. These labs offer a wide-range of custom tests that simulate the conditions of intermodal transportation, including shock, vibration and the application of various environmental conditions.

Third-party testing can also help manufacturers identify the root cause of a shipping problem through custom test programs and data analysis methods.

Since the supply chain is a complex environment with many variables and stakeholders involved, third parties can offer relief by using scientifically-controlled techniques to mitigate disputes and often reach a solution more quickly and cost-effectively.

A likely path to preventing an increase in damage is predicting the effects of an intermodal supply chain. As transportation strategies change and intermodal shipments increase, the protective performance of the packaging system must evolve to meet these demands. While logistics professionals are beginning to consider the implications of moving freight across various modes of transportation, testing can help to identify problems and uncover potential improvements. Package testing internally or through a third-party testing laboratory can help manufacturers, retailers and brand owners find the perfect mix of protection and cost to ensure their product travels safely and arrives in proper condition with a satisfied customer.

Michael Kuebler is the technical director of North America distribution testing at Smithers Pira. He guides a team of packaging experts who analyze the true impact of the supply chain on a given package at the lab in Lansing, Mich. Smithers Pira utilizes standard and non-standard package testing methods to mimic real-world handling scenarios. He is a graduate of the School of Packaging at Michigan State University with a B.S. degree in packaging engineering.

---------------------------------------

Intermodal Packaging Cheat Sheet

For logistics professionals, the primary goal is to have product where it needs to be when it needs to be there in a cost-effective and efficient manner. Here are some of the key factors to keep in mind when preparing shipments for intermodal transit:

Create a load diagram or plan.

- How are the products going to be loaded in the shipping vehicle/container?

- Are there blocking and bracing mechanisms used?

Determine how the packaging system was developed.

- Why/how was the primary, secondary and tertiary packages designed within the unit load?

- Was it tested?

Get familiar with the package testing program.

- How was the packaging tested?

- Was it tested with the load plan in mind?

If the packaging system was developed without the load plan in mind, there is a strong possibility that packaging failures will occur during shipment. Damaged freight will greatly affect one's ability to have useable product where it is supposed to be when it is supposed to be there. Keeping these things in mind when putting together a shipment plan will ultimately save time and money.