Distribution leaders are facing a combination of business and demographic changes which, if left unchecked, will force distribution center (DC) costs to quickly spiral upward. These include:

- Entry-level wages and healthcare costs are rising.

- Internet and mobile commerce are projected to double in four years, taxing demand for warehousing and fulfillment jobs—an industry well known for its high labor intensity and turnover, with associate turnover tending to accelerate as economic conditions improve.

- A shrinking and aging workforce will become less productive, and more injury-prone.

- Growing complexity in the nature of the work, while at the same time the values and beliefs of entry-level replacements in the workforce are changing (i.e., the Millennials).

Furthermore, distribution leaders often face a series of internal barriers (outlined below) which marginalize their ability to achieve breakthrough performance in DC productivity, even when investing heavily in warehouse automation and productivity technologies. The good news is, armed with the proper tactics and navigational aids, there is a proven path forward.

The Case for Change: How to Offset a $15 Minimum Wage

Several states have already enacted legislation directing an increase to a $15/hour minimum wage. Companies operating in these states face a 40+% increase in wages, in a very short period of time. Consider:

- California's change occurs over a six-year span, an increase of +7% per year.

- New York companies must raise starting wages to $15/hour in two years, an increase of +21% per year.

- This can add as much as $1 million in incremental annual payroll for every 110 hourly full-time equivalents (FTEs) working in your DC.

Where can U.S. companies find offsetting benefits in their P&L of this magnitude?

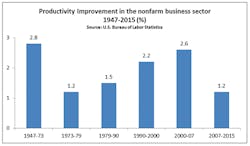

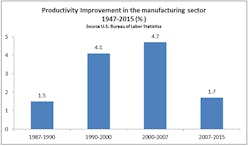

For most companies, the answer historically has not been an increase in worker productivity. In fact, U.S. companies typically average a mere 2-3% annual productivity improvement (see Figures 1 and 2).

This gap creates an obvious drain on profits. Winners in this imminent business climate will require new methods, skills and a focus on quality of execution.

Barriers & Challenges

In many ways, distribution leaders simply do not have the time and/or are not given the resources they need to address these challenges adequately. Even if you have implemented a state-of-the-art WMS, voice pick/pick-to-light, AS/RS, robotics, and conveyance systems, ultimately higher levels of DC productivity will require:

- Highly engaged, motivated, productive workers consistently executing well-designed processes with minimal wasted effort; and

- Workers who are scheduled, directed and well-coached by floor supervisors, who are all working towards the same goals utilizing the same management processes and tactics.

- Yet we often find that while virtually all DCs excel at doing what it takes to get all the orders out the door every day, there is often what we call a "Groundhog Day" approach to DC management—yesterday is forgotten and today we focus on today's loads, with occasional visits from the corporate supply chain team that dedicates 1-2 days/week to special projects at that facility.

Common barriers symptomatic of this situation include:

- Supervisors who are often promoted from within, promoting the same way of doing things.

- Inconsistent management styles and skill levels across different sections of the facility.

- Too many metrics, yet few/none that an individual associate, team of associates, or floor supervisor can influence directly on a daily basis.

- Little focus on consistent, ongoing productivity improvement.

- Lack of bandwidth and leadership experience at the superintendent and operations manager levels (they can't spend 100% of their time training and coaching).

- Inadequate training budgets/programs focused on warehouse supervisors.

- High hourly associate turnover, with the primary exit reason being they "don't feel appreciated."

- Large variation in individual associate productivity.

- Over-reliance on individual associate incentives and technology, with a lack of team-based measures/incentives (for both hourly associates and floor supervisors).

Actual results with 30 different DCs indicate a 15%+ hourly labor productivity improvement can be achieved in 90-120 days by addressing these barriers.

Keys to Achieving Breakthrough Performance

Achieving breakthrough performance is best accomplished when it is clearly understood that a leader's job is to set bold goals, develop strategies for achieving them, and ensure the organization has the resources to accomplish them. Their "job" is to lead, not to get tied up in daily execution themselves.

Your distribution leaders are experts in network design, transportation management, workflow optimization, WMS, workforce scheduling, facilities management, slotting and inventory control. These activities consume their day.

Coaches help performers overcome the natural conflict between execution and improvement. This is as true for the best athletes and sports teams as it is for business leaders and their teams. In a DC, the coach can focus exclusively on improvement of the work effort, and managers can remain focused on execution while learning new skills being modeled by coaches.

Another key to achieving breakthrough performance is to utilize a thorough structured process for creating a performance-driven culture characterized by goals, measurement and performance feedback, and dominated by positive reinforcement. It's powerful to see a mature building where every department is working toward safety, productivity and accuracy goals, as determined by the employees, and celebrating success in a manner reinforced by those same teams. Results will be driven by:

- Motivation—providing an incentive to increase individual discretionary effort, getting to the point where your associates push themselves to do everything they can.

- Sense of Team—Associates will work together to accomplish more and win, including peer pressure and peer-to-peer coaching on best practices).

- Process Improvement—Associates will be highly motivated to surface any performance barriers and bring improvement ideas to management's attention).

Finally, the new tactics must be sustained. Sustainability is achieved by building these new tactics into the day-to-day management system and meetings already in place, not to hold a series of separate discussions or treat this as a one-time project. Behavioral research indicates that it takes 21 days to adopt a new standard of behavior, or "habit." Therefore, it is imperative management stays the course and consistently reinforces the desired behaviors until the new tactics are fully baked into the day-to-day management system.

We have implemented these best practices in a range of environments, and find these approaches are applicable and the results consistent (11% to 20+% in ~ 90 days) regardless of the characteristics associated with an individual DC:

- Highly automated or manual

- Item selects, case picks and full pallet selects

- Unionized or non-unionized

- Individual incentive program or none

- New vs. old, large vs. small facilities.

The world's best athletes want to play on the best teams for two reasons—they know it improves their personal performance, and they want to win. In your facility, the greatest role you can play is to provide your distribution leaders the encouragement, support and resources they need to get past the barriers and doubts, and lead your network of DCs to achieve breakthrough performance.

Warren Bishop is a senior director of The StratOps Group, a management consulting firm. He has 20+ years of experience in supply chain management, distribution and fulfillment operations. He has held director/VP/SVP roles with Sears, Target, Toys-R-Us and Macy's. He is also a former Captain with the U.S. Army.

Bruce Miles is CEO of The StratOps Group, with 30+ years of experience in business strategy, operational excellence, and supply chain management. He is a former divisional chief supply chain officer and COO with Philips, consulting partner & national practice leader with Ernst & Young, managing director at AlixPartners, and distribution sector executive at IBM.