Finished Goods Inventories Fall, Order Fill Rates Rise

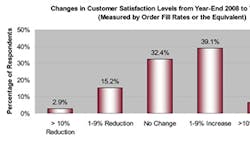

More than half of the companies in a new survey saw a decrease in inventory levels in 2009. Despite these reduced inventory levels, customer satisfaction remained the same or improved for nearly 80% of these companies, according to a recent Finished Goods Inventory Management Report by Tompkins Supply Chain Consortium.

“In 2009, companies worked very hard reducing inventory levels to improve cash flow and positively impact company financials,” says Bruce Tompkins, the Consortium’s Executive Director and author of the report. “The expectation was that order fill rates would be negatively impacted as shortages and stockouts became prevalent. However, the reality is just the opposite: Order fill rates actually improved.”

The report, which is based on a survey of leading manufacturing and retail companies, reveals that while the economy sagged and sales were off, companies found ways to substantially reduce their finished goods inventory levels. The top five reasons for these inventory changes given by survey participants are:

Smarter planning (21%);

Drop in sales (21%);

Management focus (20%);

Sales growth (11%); and

Inventory mix (5%).

In general, inventory management is performed at the corporate level. However, if the organization is very large, division-wide management is most often found. An inventory management department is often responsible for setting finished goods inventory targets, but the responsibility is typically shared by several supply chain functions.

Inventory turns, inventory balances and days of supply are the top three measurements used for finished goods inventory.

The supply chain areas in which changes are most needed with respect to this type of inventory are processes, people, and inventory policies.

For additional results from the Finished Goods Inventory Management Report, visit: http://www.tompkinsinc.com/finished-goods-inventory