The Competency you Keep — When Outsourcing Logistics

If you want a quick answer to the question, "What's new with 3PLs?" 4PLs would be as concise as you could get.

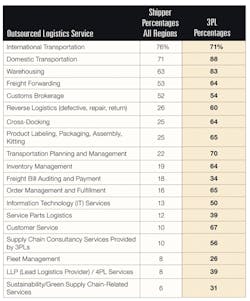

While 4PLs have been around quite a while, the real news is the renewed attention they're getting. A "fourth-party logistics (4PL) provider" is one that may manage multiple 3PLs to take on a wider range of services for shippers. According to the 17th annual 3rd party logistics study performed by Capgemini Consulting in conjunction with Penn State, Panalpina, and EyeForTransport, while transactional, operational and repetitive activities tend to be the most frequently outsourced, as supply chain complexity increases, so do more strategic specialty services such as order management and fulfillment, IT services, supply chain consulting, fleet management and even sustainability management.

See Also: Transportation & Distribution Logistics News & Analysis

This year, 52% of shippers say fuel efficiency and carbon emissions have become an important part of their 3PL procurement decision processes, the report's authors note. In Latin America 60% of shippers now see these data as important, although those relying on 3PLs to provide such services are still in the minority.

For proof that 4PL offerings are becoming more important to shippers, look no further than the International Warehouse Logistics Association (IWLA). Transportation Insight recently became the first 4PL to become a member of the association. They'll have a mutually beneficial relationship with 3PL members. While it will have broader access to warehouse partners to select for its clients, those partners will also be able to broaden their supply chain scope to include carrier sourcing, freight bill audit and payment, transportation management and supply chain analytics. Rick Brumett, vice president of client solutions for Transportation Insights, says business has changed drastically since he started out.

"When I grew up in the business warehousing was largely pallet in, pallet out," he says. "Small case fulfillment or interpack service were the exceptions. Now 3PLs have built interpack fulfillment modules, whether that requires a multi-level mezzanine picking platform or whether they just carve out a piece of their warehouse to do fulfillment. It's becoming a core business of most every 3PL that we deal with. The exception is when they don't have high-speed picking."

But whether or not you deal with 3PLs through a 4PL, Brummett recommends you understand how that provider performs those services, and who is responsible for them. You may want to pretend you're a 4PL in the selection process—especially if you represent a new niche for them.

"I want to know their thoughts of how they feel this new market should be served," he suggests. "I always start with their customer and go backwards. Have a really good idea of how they currently handle their business, how they want to expand into this relationship and the specific role you want this third party operator to play in meeting your needs. If as a 4PL I know those three answers we can usually come very close to delivering exactly what the customer needs."

How Sustainable Are 3PLs?

Another growing consideration for clients of 3PLs is their sustainability—not just environmental, but as it pertains to business viability. In fact, sustainability in every sense of the word is important to 3PLs themselves, according to members of the International Warehouse Logistics Association who participate in IWLA's Sustainable Logistics Initiative (SLI). The SLI program helps warehouses assess the effectiveness of their organization's environmental performance using various metrics. The organization receives independent verification of the effectiveness of its "green" efforts.

One of the IWLA members taking advantage of this verification is Peter Wilson, president of Sonwil Distribution Center Inc., Buffalo, NY. He admits that he doubted the importance of the initiative at an early meeting where it was discussed.

"Then I got back to my office and one of my customers called to inform us of their company's sustainability initiatives and said, ‘Either you're onboard or you're out.' We were able to tell them that we had an initiative with our association. We got involved with the SLI and got educated on what we had to do. Now, as far as this customer is concerned, we are one of the industry leaders with our sustainability initiatives."

The SLI began in 2011 after the idea was turned into reality by then-IWLA chairman Linda Hothem, who serves as CEO of Pacific American Group and senior advisor to Matson Global Distribution Services Inc. She's based in Sausalito, Calif.

Richard Murphy, president of Murphy Warehouse Company, Minneapolis, enjoys another potential benefit of the SLI that he hadn't expected when he was applying for a small business loan for a new logistics facility. The Small Business Administration loan officer told him his project would not have qualified because of its employee-to-square foot ratio, but since Murphy was incorporating sustainability projects into the new facility, it was automatically entered into the program.

Not only did his company get the loan, but Murphy managed to obtain it at a more favorable interest rate than he had thought possible.

This 350,000 sq. ft. building is LED lighted and is equipped with motion sensors to keep it fully lit when the space is occupied. It also has exterior LED lighting on motion sensors to allow the lights to run at 20-25% of lumens normally and once a driver shows up and needs more light, their tripping the motion sensor brings the lights up to 100%.

This facility also has solar power, energy-efficient HVAC systems, and this spring will be planted with 90 trees and three acres of native prairies. The building is under LEED and Energy Star review this year and Murphy is aiming for LEED Platinum certification, with a fall back to Gold. Murphy currently has two facilities that are LEED Gold certified and one that is LEED Silver. All are Energy Star Certified and the company is also ISO 14001 Certified.

"Our total solar power production of 320KW makes us the fifth largest producer in Minnesota and we are adding another 100KW this spring," he says. "Another solar project we are installing is a system that feeds a battery system to become our office and IT emergency backup (vs. relying on a diesel generator) and the specifications are in the 8-9 hour of backup range."

Such continuous improvement is a measurement benchmark of the SLI program. The data-collection technology employs Internet-based tools and the process is verified by The Sustainable Supply Chain Foundation.

To show continuous improvement, as each facility's metrics improve, it is designated as having achieved a silver, gold or platinum level. Linda Hothem believes such certification serves a useful purpose for shippers.

"To date, there is no standardization on how shippers are measuring sustainability," she says. "It is arbitrary and difficult to compare one vendor to another, which puts them in a difficult position and creates more work for them. In the near future, Dr. Dale Rogers of Rutgers University and I would like to scale SLI to measure the entire supply chain process—from raw materials to finished product—creating metrics for all segments of the supply chain."

Global Partnerships

Another factor driving shippers to 3PLs is the complexity of participating in global trade. The risks associated with regulations and global supply chains is increasing both in terms of service disruption and brand and product reputation. That's why an important consideration when selecting a 3PL partner to help serve global markets is having a local presence in those markets. That helps in navigating customs requirements and understanding how to work with in-country organizations to get product moved and keep shipments on time.

This trend could affect the longevity of 3PL relationships, according to Capgemini's Shanton Wilcox.

"We think there will be a shift to selecting one or two key 3PL relationships that will be more strategic and long term, resulting in more investment on both sides of the relationship in IT and big data," he says.

These relationships will be dedicated to ensuring supply chain visibility and overcoming the obstacles to that goal.

"The biggest barrier to true supply chain visibility is the integration of information flows from one supply chain partner to another," Wilcox continues. "Not just integration but data standardization and making sure all the information is consistent so you don't have to guess about it or do additional work once you get it. You can look at it, understand it, internalize it and make decisions."

Cloud-based technology is opening the playing field to participants of all sizes, both on the shipper and the 3PL sides. That means a wider range of 3PLs can offer more sophisticated information management capabilities, so the fact more offer this service means shippers can't rely on technological sophistication as the sole criterion for partnering with them. A better indicator of competence might be the industries the 3PL serves. For example, a 3PL's ability to offer less-than-containerload services in pharmaceuticals requires precise management of many regulatory details.

"Such a 3PL must not only know that for one company it is shipping four pallets of a product, but what is that product?" Wilcox advises. "What are the handling characteristics and regulatory requirements? They need a full profile on that product so they know if they put four pallets of another pharmaceutical company's products next to it in a container, they're not creating a problematic mixture. From a regulatory perspective, they must make sure they can ship both of those products in the same container without separation because mixing the two together may create a caustic reaction."

"The 3PL can say, ‘You may not represent a lot of business for us, but you're a profitable business and the effort it takes to onboard you is minimal because we're already in the cloud and we have most of your other trading partners up and running in other supply networks,'" Wilcox explains.

The bottom line for establishing a partnership with 3PLs, or a 4PL for that matter, is to know thyself. If you are to manage margin and maintain expectations, you have to understand what capabilities you're willing to invest in, what responsibilities you'll be dedicated to and how your partner will support you as your business changes. Managing this relationship is not a part-time job. Just structuring an agreement and then making sure it's followed on a day to day basis will demand diligence. Look at that 3PL as an extension of your company because your choice will be seen as an extension of you.

About the Author

Tom Andel

Editor-in-Chief

Tom Andel is an award-winning editorial content creator and manager with more than 35 years of industry experience. His writing spans several industrial disciplines, including power transmission, industrial controls, material handling & logistics, and supply chain management.