Integrated Goods-Handling Technologies

Quicktron Robotics has launched the QuickMix suite of integrated goods-handling technologies, including G2P systems, QuickBin+, QuickBin Ultra, QuickCube, and Mixed Picking Workstations.

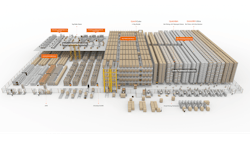

The QuickMix hybrid solution combines tote-to-person, shelf-to-person, pallet-to-person, high density storage, and flexible transport into a single robot control system platform. Designed for multi-robot collaboration, QuickMix enables operations to adapt to complex and rapidly changing needs.

QuickMix fits multiple Quicktron components into a larger integrated strategy. Within its pallet-level end-to-end automation platform QuickCube, Quicktron replaces conventional lifts with compact lifts (2-direction) embedded directly into rack rails, working in tandem with its self-developed four-way shuttle bots to achieve ultra-dense pallet storage. By removing the bottom rack level, QuickCube can also integrate a G2P shelf-to-person system. For outbound flows, submersible mobile robots handle pallet transfers to buffer zones, from which Quicktron’s omnidirectional unmanned forklifts move pallets to loading docks.

The QuickCube “pallet storage-up, picking-down” system can also replenish QuickBin Ultra high-density tote storage. As a high-throughput vertical tote-handling system capable of up to 3 m/s vertical lift speed, QuickBin Ultra pairs the bin pickers A5 high-speed picking vehicle (200 picks/hour) with the bin movers M5F/M5E single- or double-fork tote movers (4.5 m/s linear speed).