Forklift Market Outlook Brightens

Due to the fact that the forklift market is entering a structural growth cycle, Interact Analysis significantly upgraded its latest forecast.

The group says that annual forklift shipments will exceed 3.6 million units in 2034.

This marks an increase of approximately 400,000 units compared with previous forecasts.

Three trends are reshaping the market:

The automation wave reshaping material handling

The rise of autonomous forklifts is driving faster fleet upgrades and increasing unit value. Autonomy transforms forklifts into connected assets, enabling shorter replacement cycles and higher investment per truck.

Beyond replacing manned models, automation creates demand for smart handling applications. Integrated with warehouse systems, autonomous forklifts operate continuously and perform in data-sensitive environments where conventional equipment fails.

This combination—fleet replacement with higher-value units and new application demand—positions autonomous forklifts as the fastest-growing segment, with shipments forecast to grow nearly 20% annually over the next five years.

- Electrification transition enters the fast lane

The growth in electric forklift shipments is driven by two key factors: the replacement of older fleets and the creation of new demand:- Li-ion technology is accelerating the replacement of older internal combustion engine (ICE) and previous-generation Lead-Acid electric forklifts. Companies are upgrading because Li-ion offers a lower total cost of ownership, with greater efficiency, less maintenance, and faster charging—turning equipment into a productivity asset.

- Electrification is generating pure incremental demand. A major source of growth, especially in segments like walkie pallet trucks (Class 3.1), comes from replacing manual pallet jacks and trolleys. This shift is driven by labor shortages, ergonomic needs, and efficiency gains, representing a high-ROI investment with stable demand.

This dual dynamic supports our volume forecast. Li-ion is expected to become the dominant battery technology in new electric forklifts by 2026, exceeding an 80% share by 2034. China plays a central role, with its domestic Li-ion forklift shipments projected to surpass 1 million units by 2034, supported by strong policies and a mature supply chain.

Emerging markets as new growth drivers

Emerging economies in Southeast Asia, the Middle East, and Africa are injecting strong momentum into the forklift market through infrastructure expansion, manufacturing relocation, and the rise of local e-commerce.

Among them, the Indian market is particularly outstanding, with order growth projected at over 11% in both 2025 and 2026.

Deep divergence in regional market patterns

- China and India: Dual-core drivers

China is not only the world’s largest forklift producer and consumer, but also the dominant force in technological evolution and price revolution. Its Class 3.1 small electric forklifts have achieved economies of scale and low cost, with unit prices falling to around $1,000. Driven by the “Make in India” initiative and infrastructure policies, India has become one of the fastest-growing markets, with expanding local manufacturing and logistics sectors driving sustained equipment demand. - North American market: moderate recovery

Following a contraction in 2024, the US forklift market remained essentially flat in 2025, with shipments declining by approximately 1%. However, new order growth jumped 7.3% during the year, signaling a strong recovery expected in 2026. This rebound will be supported by resilient manufacturing activity, renewed investment in automation, and normalized inventory levels.

Nevertheless, North America continues to lag behind Europe and Asia in electrification. This gap is most apparent in Class 4/5 forklifts, where internal combustion engine (ICE) models retain a significant market share due to entrenched operational preferences and persistent infrastructure compatibility issues. - European market: strength in the South, stability in the North

Overall European growth is stable, but internal differences are significant. Southern European countries like Spain and Italy show strong performance, while traditional industrial powers like Germany and France are experiencing moderate growth. Eastern Europe, due to cost advantages and increased foreign investment, has become a regional highlight for growth.

Product structure evolution

- Class 3.1 becomes the market mainstay

Driven by e-commerce growth and warehouse automation, more Class 3.1 forklifts will be shipped than any other type from 2030 onwards, supported by a robust ten-year CAGR. Chinese manufacturers, leveraging distinct cost and supply chain advantages in this segment, are reshaping the global competitive landscape. - Strong continued growth for electric products

Class 1 (electric counterbalance forklifts) and Class 2 (narrow aisle forklifts) also maintain robust growth, reflecting the spread of electrification in indoor and light-duty applications. - Structural decline of ICE models

Class 4 & 5 (ICE counterbalance forklifts) are the only category showing negative growth, with a projected ten-year CAGR of -0.5%. Stricter environmental regulations, TCO disadvantages, and corporate environmental, social, and governance (ESG) goals are collectively accelerating their market decline.

Highly concentrated end-user industry demand

Logistics and retail are the mainstay of the forklift market, collectively accounting for half of global orders in 2024. This proportion is expected to increase further over the next decade, reflecting the expansion of global supply chains and e-commerce logistics. Furthermore, industries such as food & beverage, automotive, and energy form a stable second tier, while demand from traditional sectors like construction and textiles remains relatively weak.

Future challenges and strategic directions

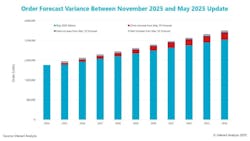

Despite improved prospects for the forklift market, it still faces challenges such as the “confidence gap” between orders and shipments, supply chain disruptions, geopolitical risks, and insufficient charging infrastructure. In response, mainstream manufacturers are transitioning from “equipment manufacturers” to “solution providers.” They are building comprehensive competitiveness centered on TCO by strengthening Li-ion battery technology, developing autonomous systems, and expanding rental and service platforms.

Competitive strategies are diverging. One path emphasizes scale and cost leadership, primarily in volume-driven segments such as Class 3.1. Another focuses on developing integrated, high-value solutions centered on automation and Total Cost of Ownership (TCO). This includes comprehensive, one-stop solutions for electric models and the development of autonomous forklifts. We will explore these two trends in depth in two further insights, to follow over the next month.